Low-maintenance woodgrain finish

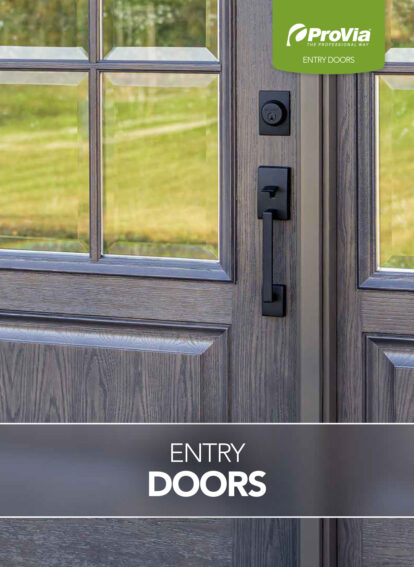

GLAZED & STAINED EXTERIOR DOORS

The beauty and character of a wood stained front door is timeless, adding a sense of warmth and depth to a home’s exterior. But wood that is exposed to the elements requires regular maintenance to keep it protected. ProVia’s fiberglass entry doors, as well as steel doors with a woodgrain finish, provide that authentic look in your choice without the maintenance of wood, making them a secure, durable, and practical option for exterior doors.

Deep browns, rich reds, light oak tones, and many options in between make up ProVia’s selection of stained front door colors. You’ll have an array of stain options depending on the type of door and door skin you choose. For a unique, weathered look, door glaze options are also available on Embarq® and Signet® fiberglass doors. Each door is factory finished in a controlled environment with our multi-step finishing systems, ensuring a consistent, beautiful, lasting finish every time.

Legacy™ Steel 420-4P French Doors in Dark Oak Stain

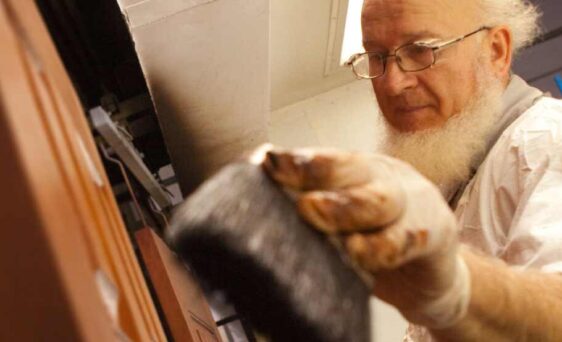

Hand-applied by craftsmen

EXTERIOR DOOR STAINS

At ProVia, stains are hand-applied by professional craftsmen, many of whom have been perfecting their work for years. Stained front door colors vary by door brand and species of woodgrain texture.

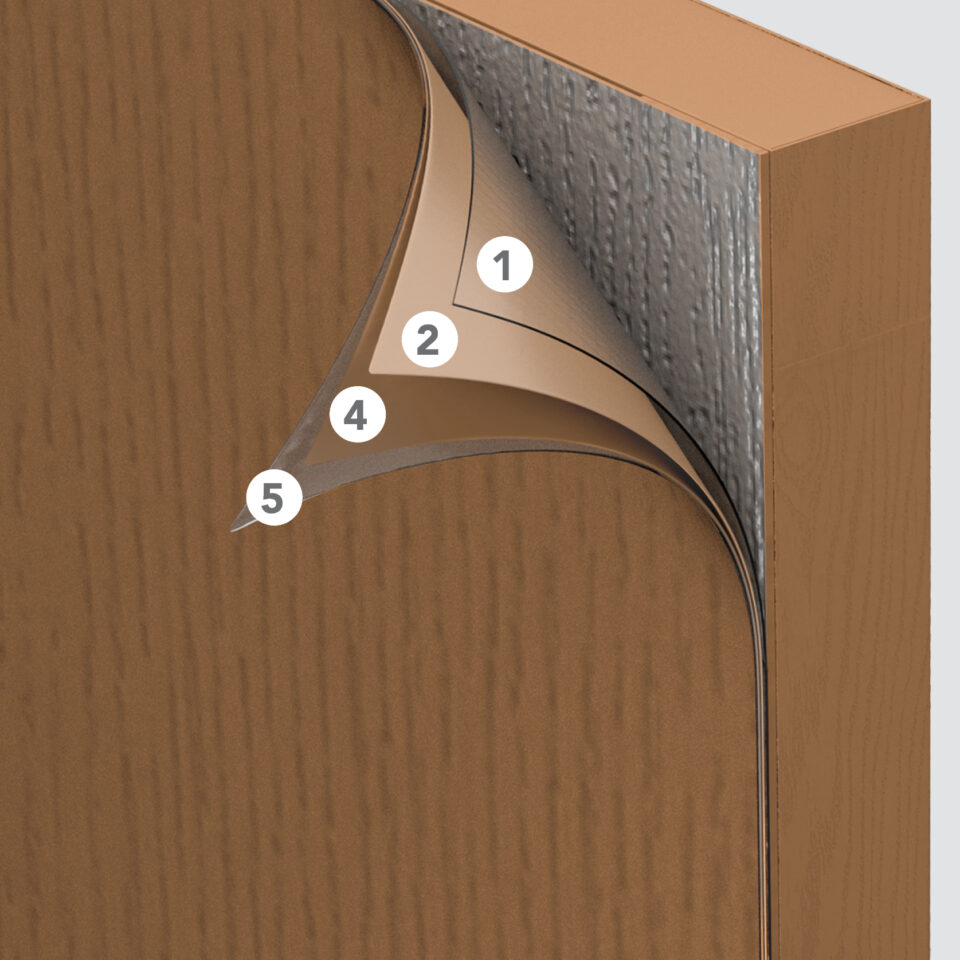

EMBARQ® & SIGNET® FIBERGLASS DOOR

STAINING PROCESS

7-step stain finishing system | 15-year finish warranty

Preparation of door using DURAFUSE™ proprietary P3 fusion preparation processes that ensure unprecedented finish durability.

Hand-staining of door using formulation exclusively designed for fiberglass doors.

Application of a layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors.

Oven-curing the door to set the clear coat for lasting durability.

Hand-sanding the door, preparing the surface for a second layer of clear coat.

Application of a second layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors.

LEGACY™ STEEL DOOR

STAINING PROCESS

6-step stain finishing system | 10-year finish warranty

Steel doors are A40 hot-dipped in galvannealed steel (300% more coating thickness than 40Z full electrolytic zinc coated steel) to resist rust inside and out.

A 2-part urethane, catalyst-hardened base coat (prime paint) is applied by a robotic reciprocating paint system.

Base coat is oven-cured for lasting durability.

Stain is hand-applied for enhanced beauty.

A layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors is applied.

HERITAGE™ FIBERGLASS DOOR

STAINING PROCESS

5-step stain finishing system | 10-year finish warranty

A 2-part urethane, catalyst-hardened base coat (prime paint) is applied by a robotic reciprocating paint system.

Base coat is oven-cured for lasting durability.

Stain finish is hand-applied for enhanced beauty.

A layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors is applied.

The door is oven-cured a second time.

ENTRY DOOR STAIN COLORS

Applied with care, by professionals. If you buy an entry system and finish it yourself, chances are it’s the first door you’ve ever stained. At ProVia®, stains are hand-applied by professional craftsmen, many who have been perfecting their work for years.

- Embarq & Signet Cherry & Mahogany stain swatches are shown below on Cherry.

- Embarq & Signet Oak, Knotty Alder & Fir stain swatches are shown on Oak.

- Heritage & Legacy stain swatches are shown on Legacy Woodgrain Textured.

- Stain finishes may look slightly different depending on the skin species selected. Always refer to our color selector for accurate color representation.

NEW!Cider Stain

Toffee Stain

American Cherry Stain

NEW!Natural Bark Stain

Nutmeg Stain

Hazelnut Stain

Cinnamon Stain

Coffee Bean Stain

NEW!Ebony Stain

NEW!Roasted Cashew Stain

Honey Wheat Stain

Almond Stain

Ginger Stain

Caramel Stain

NEW!English Chestnut Stain

Truffle Stain

NEW!Aged Barrel Stain

Espresso Stain

NEW!Urban Barnwood Stain

NEW!Ebony Stain

Natural Oak Stain

Light Oak Stain

Oak Stain

Dark Oak Stain

Walnut Stain

Cherry Stain

Dark Mahogany Stain

Hand-applied by craftsmen

EXTERIOR DOOR GLAZES

ProVia’s hand-applied glaze provides a distinctive and unique aged look for your Embarq or Signet fiberglass entry door.

EXTERIOR DOOR GLAZING PROCESS

9-step glazing system | 15-year finish warranty

Preparation of door using DURAFUSE™ proprietary P3 fusion preparation processes that ensure unprecedented finish durability.

Hand-staining of door using formulation exclusively designed for fiberglass doors.

Application of a layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors.

Oven-curing the door to set the clear coat for lasting durability.

Hand-sanding the door, preparing the surface for a second layer of clear coat.

Application of a second layer of 2-part urethane, catalyst-hardened clear coat with UV inhibitors.

The door is oven-cured a second time, creating a long-lasting, durable finish.

For a uniquely aged look

EMBARQ® & SIGNET® GLAZED FINISHES

Knotty Alder, Mahogany, Fir, Cherry & Oak (Shown on Oak)

Glaze finishes may look slightly different depending on the skin species selected. Always refer to our color selector for accurate color representation.

NEW!Driftwood Glaze

Windy City Glaze

Natural Leather Glaze

Dutch Gray Glaze

Winter Rain Glaze

NEW!Weathered Juniper Glaze

Red Velvet Glaze

Review additional options for high-quality, energy-efficient doors

entry door brands

The door, reinvented

- Most energy-efficient entry doors in the U.S.

- 43% thicker door to allow for more insulation

- Option for either Cherry, Mahogany, Oak, or Knotty Alder woodgrain finishes

- 15-year finish warranty

Durable fiberglass that looks like wood

- Most door styles and sidelite options

- Structurally superior to traditional fiberglass doors

- Option for either smooth finish or Cherry, Mahogany, Oak, Knotty Alder or Fir woodgrain finishes

- 15-year finish warranty

Value meets style and security

- Custom height in 1/8″ increments

- Oak woodgrain and smooth fiberglass finish in a variety of stains and color options

- 10-year finish warranty

Secure and beautiful

- Customize both sides of entry door with different styles or finish

- Made with 20-gauge steel, making Legacy the strongest, most durable door on the market

- Great front door solution for home security

ENTRY DOOR BROCHURE

Find all our entry door options, including door brands, accessories, hardware, finishes, and more!

EXPLORE OUR

DESIGN CENTER

Configure doors and windows, visualize products on your home, create vision boards, and more!